Airbus A380 Training Manual

Airbus A380 Technical Training Manual (TTM) Full Document New Version A380-LEVEL I - ATA 24 Electrical Power The first A380 technical manual, the 'Airplane Characteristics for Airport Planning,' was released this month. It can be consulted and/or downloaded from the A380 Family page on Airbus' web site at www.airbus.com. This is the first time a technical manual of this nature has been made available so early, some three years before the first flight of the aircraft. The Airplane Characteristics manual provides specific A380 data needed by airport authorities and planners to support the operation of the A380 within their airports. Data such as airplane dimensions, take off and landing distances, terminal operations data, taxiing, parking and pavement loading requirements are provided for the A380-800 and A380-800F, the passenger and freighter versions of the A380.

- Airbus A380 Flight Crew Training Manual

- Airbus A380 Technical Training Manual

- Airbus A380 Training Manual

Airbus A380 Technical Training Manual (TTM) Full Document New Version The first A380 technical manual, the 'Airplane Characteristics for Airport Planning,' was released this month.

Airbus has been working with planning teams from 50 major airports in five continents to ensure smooth handling of the A380 when it enters service in 2006 and the Airplane Characteristics manual is a major support for this. Following release of this first manual and up to entry into service of the A380, Airbus will deliver a full range of technical data for the maintenance, engineering, material support and flight operations departments of A380 airline customers. Technical data for the A380 will be available in electronic format according to the most recent aviation industry standards, which are more efficient and user friendly. They will be accessible through Airbus On Line Services, the Airbus portal for Customer Support.

445.6 million (2018) The Airbus A380 is a, four-engine manufactured by European manufacturer. It is the world's largest passenger airliner, and the airports at which it operates have upgraded facilities to accommodate it. It was initially named Airbus A3XX and designed to challenge 's monopoly in the large-aircraft market. The A380 made its first flight on 27 April 2005 and entered commercial service on 25 October 2007 with. An improved version, the A380plus, is under development. The A380's upper deck extends along the entire length of the, with a width equivalent to a wide-body aircraft. This gives the A380-800's 550 square metres (5,920 sq ft) of usable floor space, 40% more than the next largest airliner, the, and provides seating for 525 people in a typical three- configuration or up to 853 people in an all- configuration.

- AIRBUS A380 AND OTHER ACRONYMS AND ABBREVIATIONS. PART II - BOARD RECORD. FCTM Flight Crew Training Manual. FCU Flight Control Unit.

- Head of Flight Crew TrainingHead of Flight Crew Training AIRBUS TOULOUSE A350 XWB A350 XWB –– training for the futuretraining for the future. Manual Consultation.

The A380-800 has a design of 8,500 nautical miles (15,700 km), serving the in the world (as of November 2017), and a of 0.85 (about 900 km/h, 560 mph or 490 kt at ). As of May 2018, Airbus had received 331 firm orders and delivered 226 aircraft; is the biggest A380 customer with 162 ordered of which 103 have been delivered. In mid-1988, Airbus engineers led by Jean Roeder began work in secret on the development of an ultra-high-capacity airliner (UHCA), both to complete its own range of products and to break the dominance that had enjoyed in this market segment since the early 1970s with its. Unsuccessfully offered its smaller, double-deck concept for sale.

Roeder was given approval for further evaluations of the UHCA after a formal presentation to the President and in June 1990. The was announced at the 1990, with the stated goal of 15% lower operating costs than the 747-400.

Airbus organised four teams of designers, one from each of its partners (, ) to propose new technologies for its future aircraft designs. The designs were presented in 1992 and the most competitive designs were used. In January 1993, Boeing and several companies in the Airbus consortium started a joint feasibility study of a Very Large Commercial Transport (VLCT), aiming to form a partnership to share the limited market. This joint study was abandoned two years later, Boeing's interest having declined because analysts thought that such a product was unlikely to cover the projected $15 billion development cost. Despite the fact that only two airlines had expressed public interest in purchasing such a plane, Airbus was already pursuing its own large-plane project. Analysts suggested that Boeing would instead pursue stretching its 747 design, and that air travel was already moving away from the system that consolidated traffic into large planes, and toward more non-stop routes that could be served by smaller planes.

In June 1994, Airbus announced its plan to develop its own very large airliner, designated as A3XX. Airbus considered several designs, including an unusual side-by-side combination of two fuselages from its, the largest Airbus jet at the time.

The A3XX was pitted against the VLCT study and Boeing's own successor to the 747. From 1997 to 2000, as the darkened the market outlook, Airbus refined its design, targeting a 15–20% reduction in operating costs over the existing Boeing 747–400.

The A3XX design converged on a double-decker layout that provided more passenger volume than a traditional single-deck design, in line with traditional hub-and-spoke theory as opposed to the with the, after conducting an extensive market analysis with over 200. Although early marketing of the huge cross-section touted the possibility of duty-free shops, restaurant-like dining, gyms, casinos and beauty parlours on board, the realities of airline economics have kept such dreams grounded. On 19 December 2000, the supervisory board of newly restructured Airbus voted to launch an €8.8-billion programme to build the A3XX, re-christened as the A380, with 50 firm orders from six launch customers. The A380 designation was a break from previous Airbus families, which had progressed sequentially from A300 to A340. It was chosen because the number 8 resembles the double-deck cross section, and is a in some Asian countries where the aircraft was being marketed.

The aircraft configuration was finalised in early 2001, and manufacturing of the first A380 wing-box component started on 23 January 2002. The development cost of the A380 had grown to €11–14 billion when the first aircraft was completed.

Total development cost In 2000, the originally projected development cost was €9.5 billion. In 2004 Airbus estimated 1.5 billion euros ($2 billion) would be added for a €10.3 Bn ($12.7 Bn) total. In 2006 at €10.2 Billion, Airbus stopped publishing its reported cost and then provisioned €4.9 Bn after the difficulties in electric cabling and two years delay for an estimated total of €18 Bn. In 2014, the aircraft was estimated to have cost $25bn (£16bn – €18.9bn) to develop. In 2015, Airbus said development costs were €15bn (£11.4bn – $16.95 Bn), though analysts believe the figure is likely to be at least €5bn ($5.65 Bn) more for a €20 Bn ($22.6 Bn) total. In 2016, The A380 development costs were estimated at $25 billion for 15 years, $25–30 billion, or 25 billion euros ($28 billion).

To start the program in 2000, and the loaned Airbus 3.5 billion euros and refundable advances reached 5.9 billion euros ($7.3 billion). In February 2018, after an Emirates order secured production of the unprofitable program for ten years, Airbus revised its deal with these countries to save $1.4 billion (17%): restructured terms allow to lower the production rate from eight in 2019 to six per year.

Production. A380 components on a barge In in western France, the ship exchanges the fuselage sections from Hamburg for larger, assembled sections, some of which include the nose. The ship unloads in.

The ship then picks up the belly and tail sections from in in southern Spain, and delivers them to Bordeaux. From there, the A380 parts are transported by barge to, and by oversize road convoys to the assembly hall in. In order to avoid damage from direct handling, parts are secured in custom jigs carried on self-powered wheeled vehicles. After assembly, the aircraft are flown to (XFW) to be furnished and painted. Airbus sized the production facilities and for a production rate of four A380s per month. A380 prototype on its Five A380s were built for testing and demonstration purposes.

The first A380, F-WWOW, was unveiled in 18 January 2005. It first flew on 27 April 2005.

This plane, equipped with engines, flew from with a crew of six headed by chief. Rosay said flying the A380 had been 'like handling a bicycle'. On 1 December 2005, the A380 achieved its maximum design speed of Mach 0.96, (its design cruise speed is Mach 0.85) in a shallow dive.

In 2006, the A380 flew its first high-altitude test. It conducted its second high-altitude test at the same airport in 2009. On 10 January 2006, it flew to in Colombia, accomplishing the transatlantic testing, and then it went to to test the engine operation in high-altitude airports. It arrived in North America on 6 February 2006, landing in, Nunavut in Canada for cold-weather testing. 's station on the lower deck of A380 On 14 February 2006, during the destructive wing strength certification test on, the test wing of the A380 failed at 145% of the limit load, short of the required 150% level. Airbus announced modifications adding 30 kg (66 lb) to the wing to provide the required strength. On 26 March 2006, the A380 underwent evacuation certification in.

With 8 of the 16 exits blocked, 853 mixed passengers and 20 crew exited the darkened aircraft in 78 seconds, less than the 90 seconds required for certification. Three days later, the A380 received (EASA) and United States (FAA) approval to carry up to 853 passengers. The first A380 using engines—serial number and registration —flew on 25 August 2006. On 4 September 2006, the first full passenger-carrying flight test took place. The aircraft flew from Toulouse with 474 Airbus employees on board, in a test of passenger facilities and comfort.

In November 2006, a further series of route-proving flights demonstrated the aircraft's performance for 150 flight hours under typical airline operating conditions. As of 2014, the A380 test aircraft continue to perform test procedures.

Airbus obtained for the and model from the EASA and FAA on 12 December 2006 in a joint ceremony at the company's French headquarters, receiving the A388. The model obtained its type certificate on 14 December 2007. Production and delivery delays. Naked cabin for flight tests with water tanks ballast Initial production of the A380 was troubled by delays attributed to the 530 km (330 mi) of wiring in each aircraft.

Airbus cited as underlying causes the complexity of the cabin wiring (98,000 wires and 40,000 connectors), its concurrent design and production, the high degree of customisation for each airline, and failures of and. The German and Spanish Airbus facilities continued to use version 4, while British and French sites migrated to version 5. This caused overall configuration management problems, at least in part because wire harnesses manufactured using rather than copper conductors necessitated special design rules including non-standard dimensions and bend radii; these were not easily transferred between versions of the software. Airbus announced the first delay in June 2005 and notified airlines that deliveries would be delayed by six months. This reduced the total number of planned deliveries by the end of 2009 from about 120 to 90–100. On 13 June 2006, Airbus announced a second delay, with the delivery schedule slipping an additional six to seven months. Although the first delivery was still planned before the end of 2006, deliveries in 2007 would drop to only 9 aircraft, and deliveries by the end of 2009 would be cut to 70–80 aircraft.

The announcement caused a 26% drop in the share price of Airbus' parent, EADS, and led to the departure of EADS CEO, Airbus CEO, and A380 programme manager. On 3 October 2006, upon completion of a review of the A380 programme, Airbus CEO announced a third delay, pushing the first delivery to October 2007, to be followed by 13 deliveries in 2008, 25 in 2009, and the full production rate of 45 aircraft per year in 2010. The delay also increased the earnings shortfall projected by Airbus through 2010 to €4.8 billion. As Airbus prioritised the work on the A380-800 over the A380F, freighter orders were cancelled by and, or converted to A380-800 by Emirates and ILFC. Airbus suspended work on the freighter version, but said it remained on offer, albeit without a service entry date. For the passenger version Airbus negotiated a revised delivery schedule and compensation with the 13 customers, all of which retained their orders with some placing subsequent orders, including Emirates, Singapore Airlines, Qantas, Air France, Qatar Airways, and Korean Air.

Beginning in 2007 the A380 was considered as a potential replacement for the existing serving as presidential transport, but in January 2009 EADS declared that they were not going to bid for the contract, as assembling only three planes in the US would not make financial sense. On 13 May 2008, Airbus announced reduced deliveries for the years 2008 (12) and 2009 (21). After further manufacturing setbacks, Airbus announced its plan to deliver 14 A380s in 2009, down from the previously revised target of 18. A total of 10 A380s were delivered in 2009. In 2010 Airbus delivered 18 of the expected 20 A380s, due to Rolls-Royce engine availability problems. Airbus planned to deliver 'between 20 and 25' A380s in 2011 before ramping up to three a month in 2012. In fact, Airbus delivered 26 units, thus outdoing its predicted output for the first time.

As of July 2012, production was 3 aircraft per month. Among the production problems are challenging interiors, interiors being installed sequentially rather than concurrently as in smaller planes, and union/government objections to streamlining. Production rate At the July 2016 Airbus announced that in a “prudent, proactive step,” starting in 2018 it expects to deliver 12 A380 aircraft per year, down from 27 deliveries in 2015. The firm also warned production might slip back into red ink on each aircraft produced at that time, though it anticipates production will remain in the black for 2016 and 2017.

“The company will continue to improve the efficiency of its industrial system to achieve breakeven at 20 aircraft in 2017 and targets additional cost reduction initiatives to lower breakeven further.” Airbus expects that healthy demand for its other aircraft would allow it to avoid job losses from the cuts. As Airbus expects to build 15 airliners in 2017 and 12 in 2018, Airbus Commercial Aircraft president said without orders in 2017 production should be reduced below one per month while remaining per unit and have the program continue for 20 to 30 years. Within its 2017 half-year report, Airbus adjusted 2019 deliveries to eight aircraft. In November 2017, its chief executive was confident Airbus will still produce A380s in 2027 with more sales to come, and to further develop it to keep it competitive beyond 2030. Airbus was profitable at a rate of 15 per year and is trying to drive down further but will make losses at eight per year. An order for 36 could be finalised to keep it produced beyond 2020, but the airline wants guarantees the production will be maintained for 10 years, till 2028: reducing output to six a year would help to bridge that period and would support second-hand values while other buyers are approached, but the programme would still be unprofitable.

If it fails to win the Emirates order, Airbus is ready to phase out its production gradually as it goes through its remaining orders until early 2020s. To extend the program, Airbus offered China a production role in early 2018. While state owned airlines could order A380s, it would not help their low as it lowers frequency, they do not need more volume as are already used on domestic routes and using the A380 on its intended long haul missions would free only a few. After realising efficiencies to sustain production at a lower level, in 2017 Airbus delivered 15 'very close' to production breakeven while additional savings could continue as production is being further reduced: 12 should be delivered in 2018, eight in 2019 and six per year from 2020 with 'digestible' losses. Enders is confident the A380 will gain additional orders from existing or new operators, and sees opportunities in Asia and particularly in China where it is 'under-represented'. Entry into service. A A380 at Nicknamed Superjumbo, the first A380, MSN003 (registered as 9V-SKA), was delivered to on 15 October 2007 and entered service on 25 October 2007 with flight number SQ380 between and.

Passengers bought seats in a charity online auction paying between $560 and $100,380. Two months later, Singapore Airlines CEO Chew Choong Seng stated the A380 was performing better than either the airline and Airbus had anticipated, burning 20% less fuel per seat-mile than the airline's fleet. Emirates' claimed that the A380 has better fuel economy at Mach 0.86 than at 0.83, and that its technical dispatch reliability is at 97%, same as Singapore Airlines. Airbus is committed to reach the industry standard of 98.5%. Was the second airline to receive the A380 and commenced service between and in August 2008. Followed, with flights between and in October 2008.

By the end of 2008, 890,000 passengers had flown on 2,200 flights. An A380 on approach to In February 2009, the one millionth passenger was flown with Singapore Airlines and by May of that year 1,500,000 passengers had flown on 4,200 flights. Received its first A380 in October 2009.

Received its first A380 in May 2010. By July 2010, the 31 A380s then in service had transported 6 million passengers on 17,000 flights between 20 international destinations. Airbus delivered the 100th A380 on 14 March 2013 to. In June 2014, over 65 million passengers had flown the A380, and more than 100 million passengers (averaging 375 per flight) by September 2015, with an of 98.5%. In 2014, Emirates stated that their A380 fleet had of 90–100%, and that the popularity of the aircraft with its passengers had not decreased in the past year. Improvements and upgrades In 2010, Airbus announced a new A380 build standard, incorporating a strengthened airframe structure and a 1.5° increase in.

Airbus will also offer, as an option, an improved maximum take-off weight, thus providing a better payload/range performance. Maximum take-off weight is increased by 4 t (8,800 lb), to 573 t (1,263,000 lb) and the range is extended by 100 nautical miles (190 km); this is achieved by reducing flight loads, partly from optimising the fly-by-wire control laws. And are the first two customers to have received this new option in 2013. Emirates has asked for an update with new engines for the A380 to be competitive with the around 2020, and Airbus is studying 11-abreast seating. In 2012, Airbus announced another increase in the A380's maximum take-off weight to 575 t (1,268,000 lb), a 6 t increase from the initial A380 variant and 2 t higher than the increased-weight proposal of 2010. Its range will increase by some 150 nautical miles (280 km), taking its capability to around 8,350 nautical miles (15,460 km) at current payloads.

The higher-weight version was offered for introduction to service early in 2013. Post-delivery issues During repairs following the engine failure incident, cracks were discovered in wing fittings. As a result, the issued an in January 2012 which affected 20 A380 aircraft that had accumulated over 1,300 flights. A380s with under 1,800 flight hours were to be inspected within 6 weeks or 84 flights; aircraft with over 1,800 flight hours were to be examined within four days or 14 flights.

Fittings found to be cracked were replaced. On 8 February 2012, the checks were extended to cover all 68 A380 aircraft in operation. The problem is considered to be minor and is not expected to affect operations.

EADS acknowledged that the cost of repairs would be over $130 million, to be borne by Airbus. The company said the problem was traced to stress and material used for the fittings. Additionally, major airlines are seeking compensation from Airbus for revenue lost as a result of the cracks and subsequent grounding of fleets. Airbus has switched to a different type of aluminium alloy so aircraft delivered from 2014 onwards should not have this issue. Airbus is changing about 10% of all doors, as some leak during flight. One occurrence resulted in dropped and an emergency landing.

The switch is expected to cost over €100 million. Airbus states that safety is sufficient, as the air pressure pushes the door into the frame. Design Overview. The A380 cabin cross-section with seating The A380 was initially offered in two models: the A380-800 and the A380F.

The A380-800's original configuration carried 555 passengers in a configuration or 853 passengers (538 on the main deck and 315 on the upper deck) in a single-class economy configuration. Then in May 2007, Airbus began marketing a configuration with 30 fewer passengers (525 total in three classes)—traded for 200 nmi (370 km) more range—to better reflect trends in premium-class accommodation. The design range for the 380−800 model is 8,500 nmi (15,700 km); capable of flying from Hong Kong to New York or from Sydney to non-stop. The second model, the A380F freighter, would carry 150 tonnes of cargo with a range of 5,600 nmi (10,400 km). The freighter development was put on hold as Airbus prioritised the passenger version, and all cargo orders were cancelled.

Future variants may include an A380-900 stretch–seating about 656 passengers (or up to 960 passengers in an all-economy configuration)–and an extended-range version with the same passenger capacity as the A380-800. Engine waiting for installation The A380 is offered with the (A380-841/-842) or the (A380-861) engines.

The Trent 900 is a combination of the 3 m (118 in) fan and scaled IP compressor of the 777-200X/300X technology demonstrator derived from the Boeing 777's, and the Airbus A340-500/600's core. The GP7200 HP core technology is derived from GE's and its LP sections are based on the expertise. At its launch in 2000, engine makers assured Airbus it was getting the best level of technology and they would be state of the art for the next decade, but three years later Boeing launched the 787 with game-changing technology and 10% lower fuel burn than the previous generation, to the dismay of John Leahy.

Thanks to its modern engines and aerodynamic improvements, Lufthansa's A380s have half the noise footprint of the Boeing 747-200 while carrying 160 more passengers. In 2012, the A380 received an award from the. Is a key destination for the A380. The aircraft is below the QC/2 departure and QC/0.5 arrival noise limits under the set by the airport.

Field measurements suggest the approach quota allocation for the A380 may be overly generous compared to the older Boeing 747, but still quieter. Rolls-Royce is supporting the CAA in understanding the relatively high A380/Trent 900 monitored noise levels. Heathrow’s landing charges having a noise component, the A380 is cheaper to land there than a Boeing 777-200 and -300 and it saves $4,300 to $5,200 per landing, or $15.3M to $18.8M of over 15 years. Has a similar noise charge. Sufficient braking capacity allowed for to be installed on only the inboard engines. The outboard engines lack them, reducing the amount of debris stirred up during landing. They are electrically actuated to save weight and for better reliability than pneumatic or hydraulic equivalents.

Composite photo of a structural loading test on the left wing box The A380's wing is sized for a (MTOW) over 650 tonnes to accommodate these future versions, albeit with some internal strengthening required on the A380F freighter. The optimal wingspan for this weight is about 90 m (300 ft), but airport restrictions limited it to less than 80 m (260 ft), lowering to 7.8 which reduces about 10% and increases a few percent, given that fuel costs constitute about 50% of the cost of long-haul airplane operation. The common wing design approach sacrifices fuel efficiency on the A380-800 passenger model because of its weight but Airbus estimates that the aircraft's size and advanced technology will provide lower operating costs per passenger than the 747-400. The wings incorporate that extend above and below the wing surface, similar to those on the and.

These increase fuel efficiency and range by reducing. The wingtip fences also reduce, which endangers following aircraft and could, theoretically, damage house roofs. Materials While most of the fuselage is made of aluminium alloys, comprise more than 20% of the A380's., and are used extensively in wings, fuselage sections (such as the undercarriage and rear end of fuselage), tail surfaces, and doors. The A380 is the first commercial airliner to have a central wing box made of carbon fibre reinforced plastic.

It is also the first to have a smoothly contoured wing cross section. The wings of other commercial airliners are partitioned span-wise into sections. This flowing continuous cross section reduces aerodynamic drag. Are used in the leading edges of the. The hybrid fibre metal laminate material (glass laminate aluminium reinforced epoxy) is used in the upper fuselage and on the stabilisers' leading edges. This aluminium- is lighter and has better corrosion and impact resistance than conventional aluminium used in aviation.

Unlike earlier composite materials, GLARE can be repaired using conventional aluminium repair techniques. The application of GLARE on the A380 has a long history, which shows the complex nature of innovations in the aircraft industry. Newer aluminium alloys are used in the A380's airframe. This enables the widespread use of manufacturing techniques, eliminating rows of and resulting in a lighter, stronger structure.

High-strength aluminium (type 7449) reinforced with carbon fibre was used in the wing brackets of the first 120 A380s to reduce weight, but cracks have been discovered and new sets of the more critical brackets will be made of standard, increasing weight by 90 kg (198 lb). Repair costs for earlier aircraft are expected to be around €500 million (US$629 million).

It takes 3,600 L (950 US gal) of paint to cover the 3,100 m 2 (33,000 sq ft) exterior of an A380. The paint is five layers thick and weighs about 650 kg (1,433 lb).

Airbus A380 Flight Crew Training Manual

Avionics The A380 employs an (IMA) architecture, first used in advanced military aircraft, such as the, and. The main IMA systems on the A380 were developed by the.

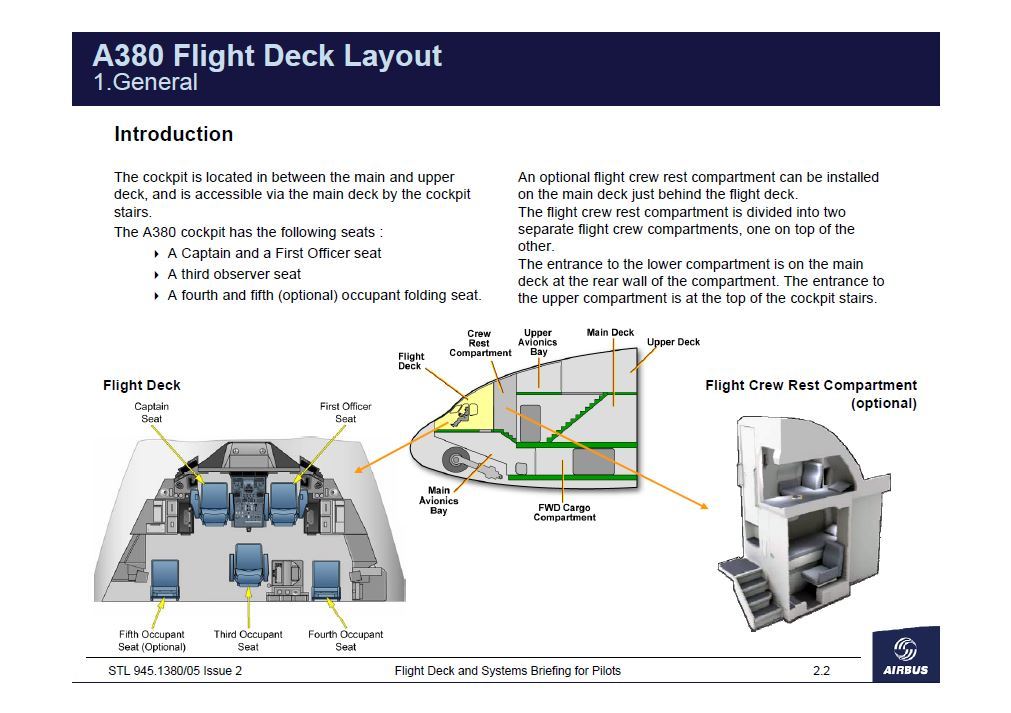

Designed and developed by Airbus, Thales and, the IMA suite was first used on the A380. The suite is a technological innovation, with networked computing modules to support different applications. The data networks use, an implementation of ARINC 664. These are switched, and based on. This reduces the amount of wiring required and minimises. A380 flight deck Airbus used similar cockpit layout, procedures and handling characteristics to other Airbus aircraft, reducing crew training costs.

The A380 has an improved, using flight controls linked to. The cockpit has eight 15 by 20 cm (5.9 by 7.9 in), all physically identical and interchangeable; comprising two, two navigation displays, one engine parameter display, one system display and two. The MFDs were introduced on the A380 to provide an easy-to-use interface to the —replacing three multifunction control and display units.

They include keyboards and trackballs, interfacing with a ' display system. The Network Systems Server (NSS) is the heart of A380's paperless cockpit; it eliminates bulky manuals and traditional charts. The NSS has enough inbuilt robustness to eliminate onboard backup paper documents. The A380's network and server system stores data and offers electronic documentation, providing a required equipment list, navigation charts, performance calculations, and an aircraft logbook. This is accessed through the MFDs and controlled via the keyboard interface.

Systems flight control actuators have been used for the first time in civil aviation to back up primary actuators. Also, during certain manoeuvres they augment the primary actuators. They have self-contained hydraulic and electrical power supplies. Electro-hydrostatic actuators (EHA) are used in the and, electric and hydraulic motors to drive the slats as well as electrical backup hydrostatic actuators (EBHA) for the rudder and some spoilers. The A380's 350 bar (35 MPa or 5,000 psi) hydraulic system is a significant difference from the typical 210 bar (21 MPa or 3,000 psi) hydraulics used on most commercial aircraft since the 1940s. First used in military aircraft, high-pressure hydraulics reduce the weight and size of pipelines, actuators and related components. The 350 bar pressure is generated by eight de-clutchable hydraulic pumps.

The hydraulic lines are typically made from; the system features both fuel- and air-cooled. Self-contained electrically powered hydraulic power packs serve as backups for the primary systems, instead of a secondary hydraulic system, saving weight and reducing maintenance. The A380 uses four 150 kVA variable-frequency electrical generators, eliminating constant-speed drives and improving reliability. The A380 uses aluminium power cables instead of copper for weight reduction. The electrical power system is fully computerised and many and breakers have been replaced by solid-state devices for better performance and increased reliability. The auxiliary power comprises the (APU), the electronic control box (ECB), and mounting hardware.

The APU in use on the A380 is the PW 980A APU. The APU primarily provides air to power the Analysis Ground Station (AGS) on the ground and to start the engines. The AGS is a semi-automatic analysis system of flight data that helps to optimise management of maintenance and reduce costs. The APU also powers electric generators that provide auxiliary electric power to the aircraft. Passenger provisions.

Etihad The Residence Apartment with bedroom, living room and an en-suite shower room on Airbus A380-800 The cabin has features to reduce traveller fatigue such as a quieter interior and higher pressurisation than previous generations of aircraft; the A380 is pressurised to the equivalent altitude of 1,520 m (5,000 ft) up to 12,000 m (39,000 ft). It has 50% less cabin noise, 50% more cabin area and volume, larger windows, bigger overhead bins, and 60 cm (2.0 ft) extra headroom versus the 747-400. Seating options range from 3-room 12 m 2 (130 sq ft) 'residence' in first class to 11-across in economy. A380 economy seats are up to 48 cm (19 in) wide in a 10-abreast configuration, compared with the 10-abreast configuration on the 747-400 that typically has seats 44.5 cm (17.5 in) wide. On other aircraft, economy seats range from 41.5 to 52.3 cm (16.3 to 20.6 in) in width. The A380's upper and lower decks are connected by two stairways, fore and aft, wide enough to accommodate two passengers side-by-side; this cabin arrangement allows multiple seat configurations. The maximum certified carrying capacity is 853 passengers in an all-economy-class layout, Airbus lists the 'typical' three-class layout as accommodating 525 passengers, with 10 first, 76 business, and 439 economy class seats.

Airbus A380 Technical Training Manual

Airline configurations range from 's 407 passengers to ' two-class 615 seats for, and average around 480–490 seats. The 's proposed 840 passenger layout has not come to fruition. The A380's interior illumination system uses bulbless in the cabin, cockpit, and cargo decks.

The LEDs in the cabin can be altered to create an ambience simulating daylight, night, or intermediate levels. On the outside of the aircraft, lighting is used for brighter illumination. Airbus's publicity has stressed the comfort and space of the A380 cabin, and advertised onboard relaxation areas such as bars, beauty salons, and restaurants. Proposed amenities resembled those installed on earlier airliners, particularly 1970s wide-body jets, which largely gave way to regular seats for more passenger capacity. Airbus has acknowledged that some cabin proposals were unlikely to be installed, and that it was ultimately the airlines' decision how to configure the interior. Industry analysts suggested that implementing customisation has slowed the production speeds, and raised costs.

Due to delivery delays, Singapore Airlines and Air France debuted their seat designs on different aircraft prior to the A380. Emirates first class shower Initial operators typically configured their A380s for three-class service, while adding extra features for passengers in premium cabins. Launch customer Singapore Airlines introduced partly enclosed first class suites on its A380s in 2007, each featuring a leather seat with a separate bed; center suites could be joined to create a double bed. A year later, Qantas debuted a new first class and a sofa lounge at the front of the upper deck on its A380s, and in 2009 Air France unveiled an upper deck electronic art gallery. In late 2008, Emirates introduced 'shower spas' in first class on its A380s allowing each first class passenger five minutes of hot water, drawing on 2.5 tonnes of water although only 60% of it was used. Emirates, Etihad Airways and also have a bar lounge and seating area on the upper deck, while Etihad has enclosed areas for two people each. In addition to lounge areas, some A380 operators have installed amenities consistent with other aircraft in their respective fleets, including self-serve snack bars, sections, and redesigned business class seating.

The Hamburg Aircraft Interiors Expo in April 2015 saw the presentation of an 11-seat row economy cabin for the A380. Airbus is reacting to a changing economy; the recession which began in 2008 saw a drop in market percentage of first class and business seats to six percent and an increase in budget economy travelers. Among other causes is the reluctance of employers to pay for executives to travel in First or Business Class. Airbus' chief of cabin marketing, Ingo Wuggestzer, told Aviation Week and Space Technology that the standard three class cabin no longer reflected market conditions.

The 11 seat row on the A380 is accompanied by similar options on other widebodies: nine across on the and ten across on the. Integration with infrastructure and regulations Ground operations. With separate for the main and upper deck, and In the 1990s, aircraft manufacturers were planning to introduce larger planes than the. In a common effort of the (ICAO) with manufacturers, airports and its member agencies, the '80-metre box' was created, the allowing planes up to 80 m (260 ft) wingspan and length to be accommodated. Airbus designed the A380 according to these guidelines, and to operate safely on Group V runways and taxiways with a 60 metres (200 ft) loadbearing width.

The US FAA initially opposed this, then in July 2007, the FAA and EASA agreed to let the A380 operate on 45 m (148 ft) runways without restrictions. The A380-800 is approximately 30% larger in overall size than the 747-400. Runway lighting and signage may need changes to provide clearance to the wings and avoid blast damage from the engines. Runways, runway shoulders and taxiway shoulders may be required to be stabilised to reduce the likelihood of caused to (or by) the outboard engines, which are more than 25 m (82 ft) from the centre line of the aircraft, compared to 21 m (69 ft) for the, and. A380 20-wheel main Airbus measured pavement loads using a 540-tonne (595 short tons) ballasted test rig, designed to replicate the of the A380.

The rig was towed over a section of pavement at Airbus' facilities that had been instrumented with embedded load sensors. It was determined that the pavement of most runways will not need to be reinforced despite the higher weight, as it is distributed on more wheels than in other passenger aircraft with a total of 22 wheels (that is, its is lower). The A380 undercarriage consists of four main landing gear legs and one noseleg (a similar layout to the 747), with the two inboard landing gear legs each supporting six wheels.

The A380 requires service vehicles with lifts capable of reaching the upper deck, as well as capable of handling the A380's maximum ramp weight. When using two jetway bridges the boarding time is 45 min, and when using an extra jetway to the upper deck it is reduced to 34 min.

Airbus A380 Training Manual

The A380 has an airport turnaround time of 90–110 minutes. In 2008 the A380 test aircraft were used to trial the modifications made to several airports to accommodate the type. Takeoff and landing separation. Left behind In 2005, the ICAO recommended that provisional separation criteria for the A380 on takeoff and landing be substantially greater than for the 747 because preliminary data suggested a stronger. These criteria were in effect while the ICAO's wake vortex steering group, with representatives from the, the FAA, and Airbus, refined its 3-year study of the issue with additional. In September 2006, the working group presented its first conclusions to the ICAO. In November 2006, the ICAO issued new interim recommendations.

Replacing a blanket 10 nautical miles (19 km) separation for aircraft trailing an A380 during approach, the new distances were 6 nmi (11 km), 8 nmi (15 km) and 10 nmi (19 km) respectively for non-A380 'Heavy', 'Medium', and 'Light' ICAO aircraft categories. These compared with the 4 nmi (7.4 km), 5 nmi (9.3 km) and 6 nmi (11 km) spacing applicable to other 'Heavy' aircraft. Another A380 following an A380 should maintain a separation of 4 nmi (7.4 km). On departure behind an A380, non-A380 'Heavy' aircraft are required to wait two minutes, and 'Medium'/'Light' aircraft three minutes for time based operations.

The ICAO also recommends that pilots append the term 'Super' to the aircraft's callsign when initiating communication with air traffic control, to distinguish the A380 from 'Heavy' aircraft. In August 2008, the ICAO issued revised approach separations of 4 nmi (7.4 km) for Super (another A380), 6 nmi (11 km) for Heavy, 7 nmi (13 km) for medium/small, and 8 nmi (15 km) for light. In November 2008, an incident on a parallel runway during crosswinds made the Australian authorities change procedures for those conditions. Singapore Airlines describe the A380's landing speed of 130–135 kn (240–250 km/h) as 'impressively slow'. Maintenance As the A380 fleet grows older, rules require certain scheduled from approved. The increasing fleet size (to about 286 in 2020) cause expected maintenance and modification to cost $6.8 billion for 2015–2020, of which $2.1 billion are for engines. Emirates performed its first for 55 days in 2014.

During lengthy shop stays, some airlines will use the opportunity to install new interiors. The A380plus winglet mockup Launched at the June 2017, Airbus offers an A380plus enhanced version with 13% lower costs per seat, featuring up to 80 more seats through better use of cabin space, split scimitar and wing refinements allowing a 4% improvement, and longer intervals with less downtime. Its is increased by 3 t (6,600 lb) to 578 t (1,274,000 lb), allowing it to carry more passengers over the same 8,200 nmi range or increase the range by 300 nm. Could order 20 aircraft at the November. The upgrade will be available from 2020.

Winglet mockups, 4.7m (15½ft) high, were displayed on the MSN04 test aircraft at Le Bourget. Will be modified and changed by increasing its height by 33 mm (1.3 in) between Rib 10 and Rib 30, along with upper-belly fairing improvements. The, the and the fuel pumps will come from the to reduce weight and improve reliability and fuel economy. Light checks will be required after 1,000 hr instead of 750 hr and heavy check will be reduced to keep the aircraft flying for six days more per year. Main article: Eighteen customers have ordered the A380.

Total orders for the A380 stand at 331 as of May 2018. The biggest customer is Emirates, which has ordered or committed to order a total of 162 A380s. One order was made in 2007 but later cancelled by Airbus.

The A380F version attracted 27 orders, before they were either cancelled (20) or converted to A380-800 (7) following the production delay and the subsequent suspension of the freighter program. Delivery takes place in Hamburg for customers from Europe and the Middle East and in Toulouse for customers from the rest of the world. EADS explained that deliveries in 2013 were to be slowed temporarily to accommodate replacement of the wing rib brackets where cracks were detected earlier in the existing fleet. In 2013, in expectation of raising the number of orders placed, announced 'attractable discounts' to airlines who placed large orders for the A380. Soon after, at the November 2013 where it ordered 150, ordered 50 aircraft, totalling $20 billion. In 2014, Airbus said that some ordered A380s might not be built for an undisclosed Japanese airline. Planned to order eight more airplanes but is in doubt due to a cost-cutting drive.

Amedeo, an aircraft lessor that ordered 20 A380s, had not found a client for the airliner as of 2014. Ordered six A380s in 2001 but never took delivery and later cancelled them in 2018. As of June 2017, Emirates has 48 orders outstanding but due to lack of space in, it deferred 12 deliveries by one year and will not take any in 2019-20 before replacing its early airliners from 2021: there are open production slots in 2019 and Airbus reduced its production rate at 12 per year for 2017-18.

The real backlog is much smaller than the official 107 with 47 uncertain orders: 20 commitments for the A380-specialized lessor Amedeo which commits to production only once aircraft are placed, eight for Qantas which wants to keep its fleet at 12, six for Virgin Atlantic which does not want them anymore and three ex for finance vehicle Air Accord. At its 100th delivery ceremony, Emirates Airline head was hoping to order new A380s at the November 2017 the following week.

Emirates does not need the small front staircase and eleven-abreast economy of the A380plus concept, but wants Airbus to commit to continue production for at least 10 years. On 18 January 2018, Airbus secured a preliminary agreement from Emirates for up to 36 A380s: 20 potentially firm orders and 16 options, to be delivered from 2020, valued at $16 billion at list prices. John Leahy is confident that Airbus will secure one more A380 order in 2018; discussions are reportedly under way with IAG for British Airways to take new A380s, which could be cheaper than refurbishing second-hand planes to its specifications. Timeline A380 firm net orders and deliveries.